What to consider when choosing a chiller. Determination of basic parameters.

1. Is the condenser cooled by air or water?

- Where will the condenser be located, indoors or outdoors?

- It is necessary to consider convenience of service, height of a ceiling, obstacles, walls, the maximum and minimum ambient temperature.

If water cooling — what is the source of coolant?

Highest and lowest condenser coolant temperatures?

- Is filtration required before the coolant enters the chiller condenser?

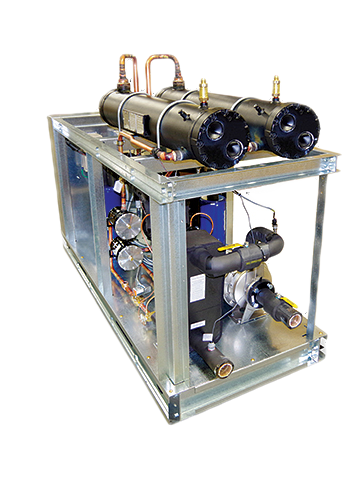

2. Monoblock chiller or with a remote condenser?

Location of the cooling system — indoors or outdoors?

Placing a chiller or condenser needs consideration.

3. How accurate temperature control is needed for your processes?

- If strict temperature control is required, you will need a dual-circuit technological chiller to maintain a certain temperature in the onboard or separate tank.

4. What voltage is available for the future chiller?

- What are the existing electricity network capacities at the facility where the chiller will be installed?

5. What liquid do you plan to cool?

Is filtering needed before entering?

- Does the fluid contain corrosive or chemical substances that can damage heat exchange surfaces?

6.What are the estimated temperatures at the inlet/outlet of the chiller?

- If the temperature is very high, a buffer tank or other measures will be needed to reduce the temperature difference at the inlet/outlet of the evaporator.

7. Direct cooling or through an intermediate refrigerant?

Determine: what type of cooling is needed?

What is the estimated freezing point of the refrigerant for the case of intermediate cooling (double-circuit system)?

8. What is the ambient temperature?

- What is the lowest temperature of the liquid at the outlet of the chiller during operation?

What is the lowest ambient temperature (winter)?

What is the highest ambient temperature (summer)?

9. What volume of liquid needs to be cooled for a certain time?

- It is necessary to indicate the estimated volume of liquid cooled over time (consumption of the consumer pump, cubic meters per hour).

10. Is a system pump required for the chiller?

Is there already a technological pump in the circuit?

If there is no pump, what are the flow and pressure requirements in the technological process?

Relevant articles