What works we perform.

Liquid cooling systems are widely used in the production of juices, drinking water, alcoholic beverages.

In the production of juices and nectars, cooling is used for processes of:

- cooling after pasteurization;

- cooling on the product bottling line;

- storage in specially designated warehouses at the factory.

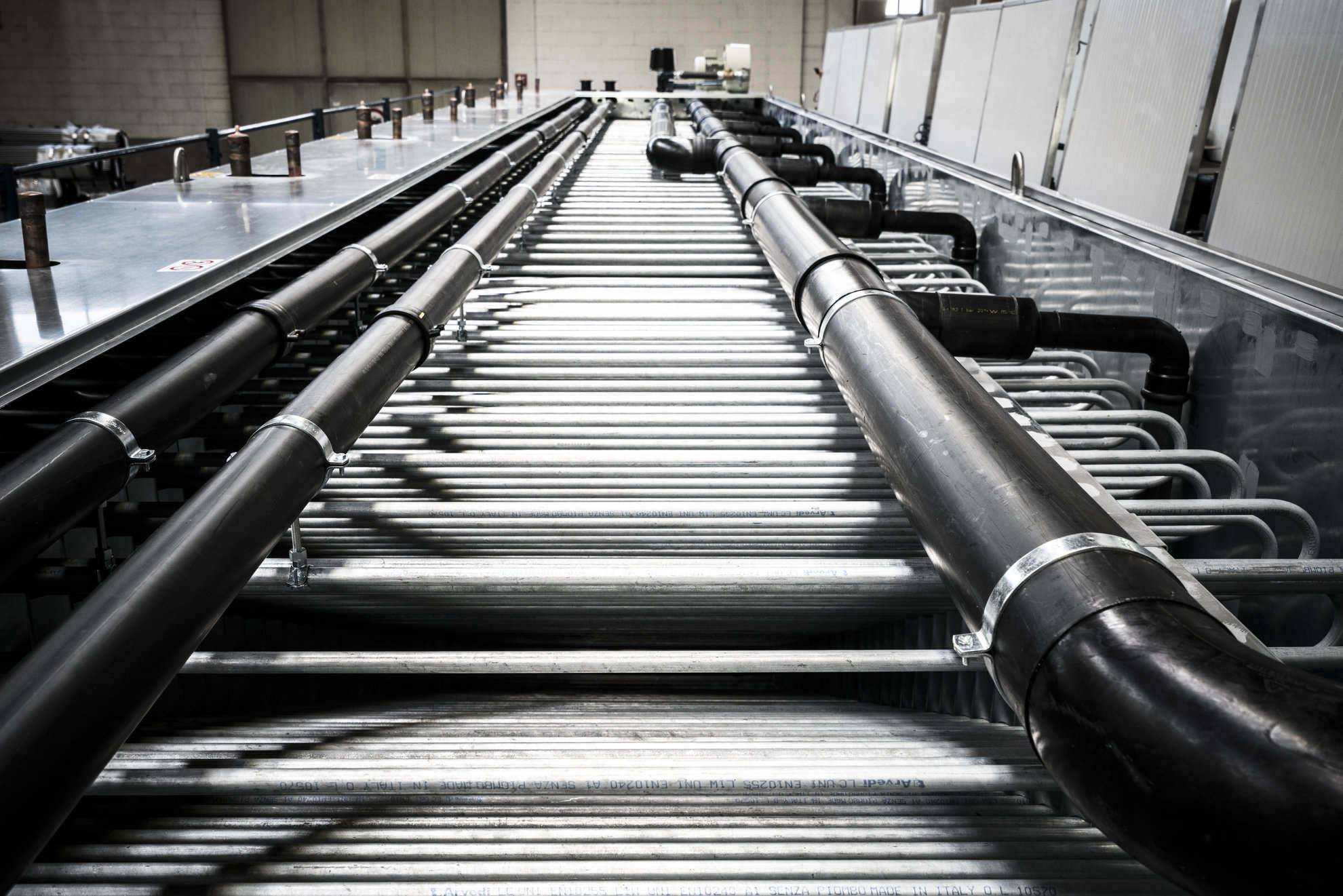

Liquid cooling systems (chillers) and heat exchanging machines (heat exchangers) are used.

As a rule, cooling takes place not directly in heat exchangers (freon-finished product), but by means of application of the special heat carrier on the basis of propylene glycol (double-circuit cooling: freon-antifreeze / antifreeze-finished product).

In the production of drinking water, it must be cooled before bottling. For this purpose, liquid cooling systems (chillers) together with heat exchanging machines (heat exchangers) are also used.

Cooling takes place in two circuits (freon-antifreeze / antifreeze-finished product). An aqueous solution of propylene glycol acts as an intermediate coolant.

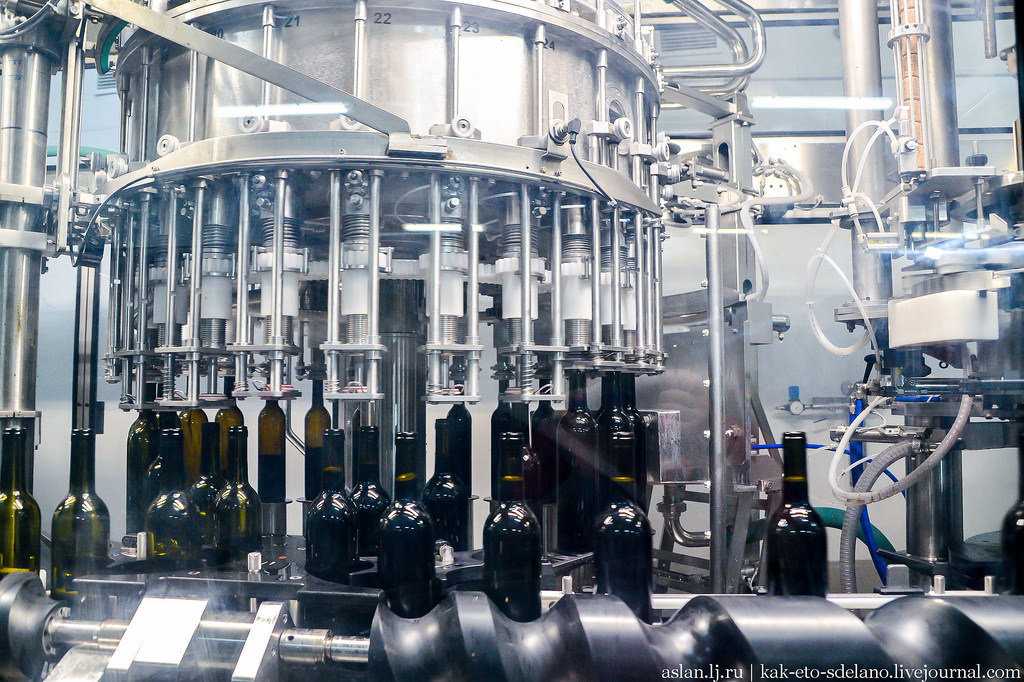

In alcoholic beverage production, depending on the technology and type of finished product, cooling is used at several stages of production:

- cooling of wine material;

- cream of tartar sediment;

- exposure with a gradual decrease in temperature and subsequent storage in acratophores;

- cooling of finished products before bottling.

An aqueous solution of propylene glycol acts as an intermediate coolant.

The following equipment is used for cooling liquids:

- liquid cooling systems (chillers);

- heat exchanging machines (heat exchangers).

It should be noted that all heat exchange equipment for food production, in case of contact with the finished product, must be made of “food” stainless steel.

Comprehensive solutions for refrigeration systems for cooling liquids in the consumer segment.

We carry out a full cycle of “turnkey” services — general design, calculation of capacities, selection of necessary machines, installation, commissioning, service, and also reconstruction and modernization of systems for cooling liquids.

Our experts will help you evaluate different types of refrigeration systems, select the most efficient and cost-effective technical solution that will meet your long-term maintenance requirements and budgets. We provide a warranty on the equipment from the manufacturer and the work performed.