What works we perform.

Liquid cooling systems that do not belong to the ACS are used to cool production equipment, such as:

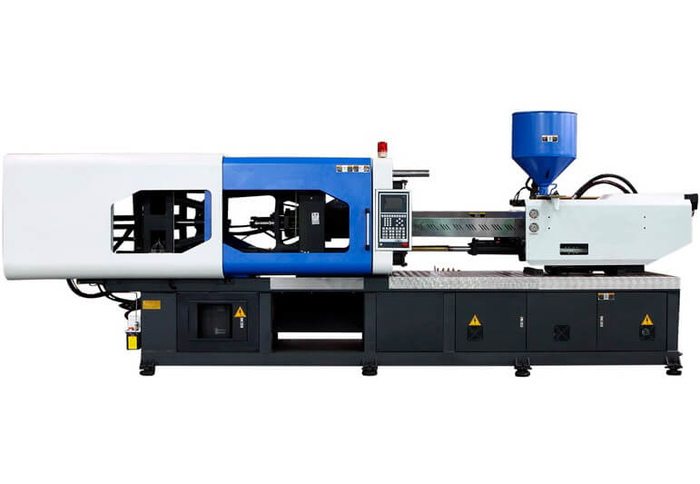

- injection molding machines,

- shafts of printing machines of printing houses,

- cooling of oil in the production machines,

- maintaining the set temperature of cutting devices and cutting material,

- cooling of liquid in tanks for hardening of metal workpieces,

- cooling of acids for baths of anodizing,

- cooling of intermediate refrigerants of reactors’ cooling jackets,

- and many other things.

The use of liquid cooling systems for the industrial sector can be divided into two types:

- chillers for ventilation and air conditioning of industrial premises;

- chillers for cooling production equipment and machines.

Liquid cooling systems for ventilation and air conditioning are usually either «chiller-fancoils» or «balanced ventilation system».

In the first case («chiller-fancoils»), the liquid cooling system works together with fancoils and provides direct conditioning of the working areas of production.

In the second case («balanced ventilation system»), the liquid cooling system is used in the operation of the cooling section of the supply and exhaust unit to provide the required air conditioning in the production.

At cooling chillers of various layouts (monoblock execution, without the condenser of air cooling) complete with the hydraulic module are applied. Depending on the need and complexity of production processes of cooling, heat exchanging machines of different types are used:

- collapsible plate heat exchanger;

- brazed plate heat exchanger;

- shell and tube;

- pipe in the pipe.

Heat exchangers can be made of steel, stainless steel, acid-resistant alloy.

Comprehensive solutions for refrigeration systems. Injection molding machines.

We provide a full cycle of “turnkey” services — general design, capacity calculation, selection of necessary machines, installation, commissioning, service, as well as reconstruction and modernization of systems for cooling liquids at the light and heavy

industries.

Our experts will help you evaluate different types of refrigeration systems, select the most efficient and cost-effective technical solution that will meet your long-term maintenance requirements and budgets. We provide a warranty on the equipment from the manufacturer and the work performed.