What works we perform.

The best way to increase the shelf life of products is shock freezing, which can be used for almost any product: meat, poultry, fish and seafood, various meat and fish semi-finished products, fruits and vegetables, berries, mushrooms. It is also possible to organize the process of hardening ice cream, freezing fish products, etc.

The undeniable advantages of shock freezing are:

- powerful productivity that allows to freeze production in various volumes;

- ecological purity of frozen products, as no heat or chemical treatment is required;

- up to 90%: retain all the useful vitamins and trace elements and reduce weight loss.

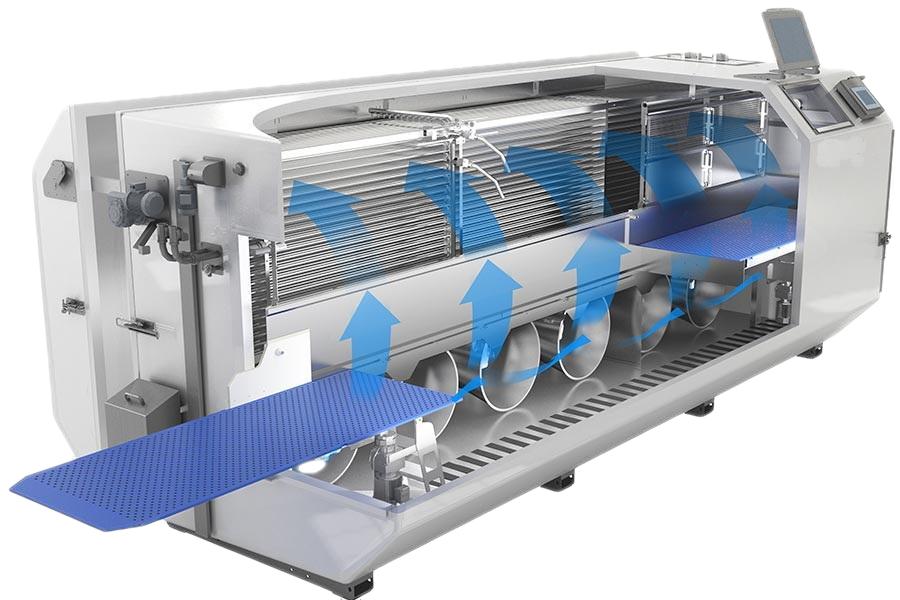

Freezing IQF tunnels carry out fast freezing of fruit and vegetable

and berry products with minimum shrinkage. Main advantages:

- preservation of product appearance, useful properties, crumbliness and shape of products;

- high productivity — up to 10 tons per hour;

- delivery in assembled form, which simplifies the process of mounting and embedding the equipment.

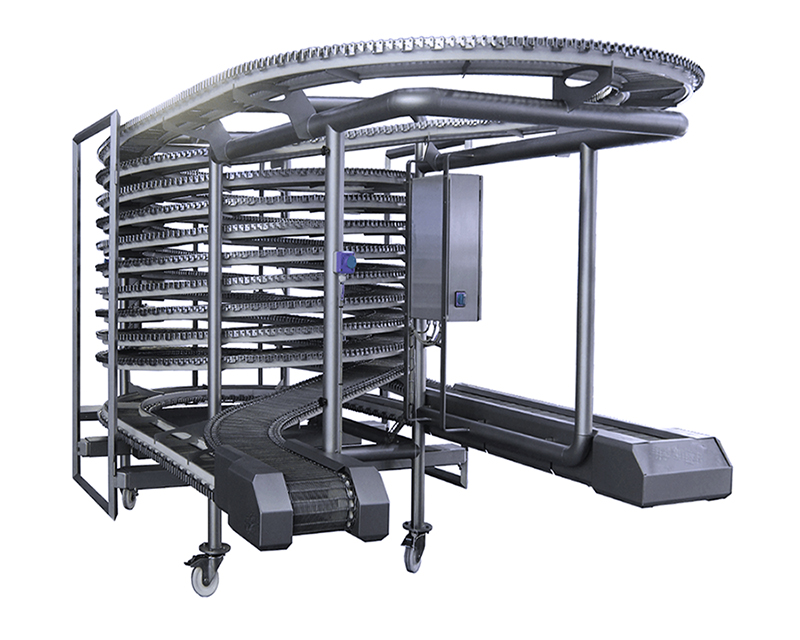

Spiral freezer tunnels are designed for rapid deep freezing of large

volumes of products. Main advantages:

- preservation of taste and chemical properties of the goods;

- maximum process automation;

- productivity up to 100 tons per day.

Mistakes and unjustified savings in the design, construction and selection of equipment can be critical, as a result of which crop losses can exceed the cost of the investment itself.

Comprehensive solutions and equipment for shock freezing.

We offer comprehensive calculation, design, supply and installation of equipment for shock freezing from the world’s best manufacturers. Full “turnkey” construction cycle. Warranty on works and equipment.

Our experts will help you evaluate different types of refrigeration systems, select the most efficient and cost-effective technical solution that will meet your long-term maintenance requirements and budgets. We provide a warranty on the equipment from the manufacturer and the work performed.