What works we perform.

Pre-cooling is a vital post-harvest stage that is necessary before storage. The main purpose of pre-cooling is to remove heat from the berries and fruits after harvest, because there is a big difference between the temperature of the harvest and the warehouse for cooling.

Cooling rate is an important point in setting the cooling mode and depends on the length of time between harvest, the beginning of its cooling and the initial temperature of the berry. Thus, pre-cooling reduces the respiration rate of the fruit, prevents weight loss and overripeness, extends the shelf life of the crop. In addition, pre-cooling also inhibits the growth of various microorganisms, reduces the risk of disease, rot and bacterial growth.

There are 2 main types of cooling:

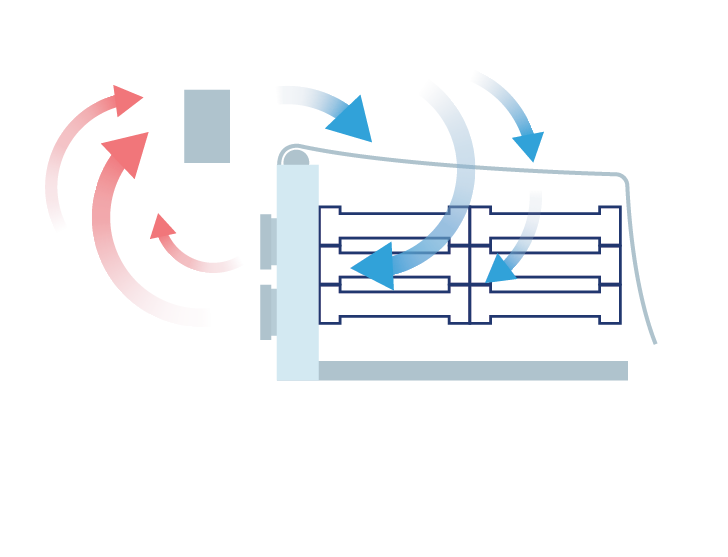

Forced cooling removes field heat by means of ventilation systems. Cold air circulates in it at high speed. This method is effective for pre-cooling of packaged berries and stone fruits. This is achieved by means of a specialized ventilation unit, which is mounted in the refrigerator in an additional wall.

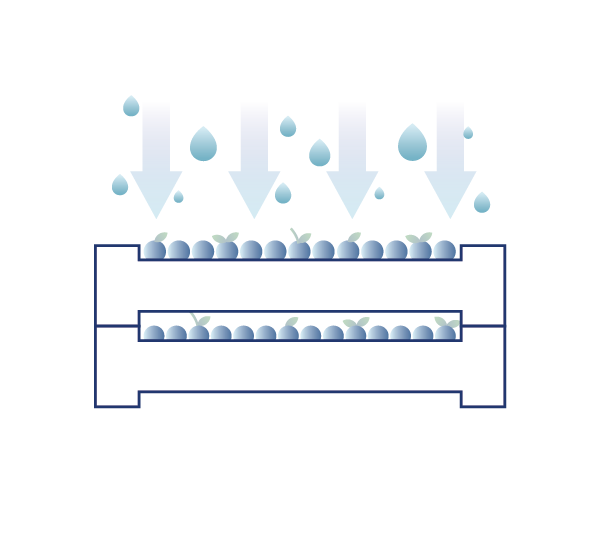

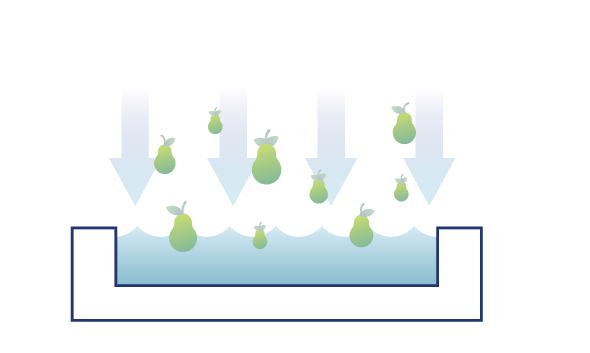

Hydro-cooling is one of the most common and effective methods of pre-cooling.

The method includes spraying (suitable for small berries and accelerates the cooling process); or immersion of the product in cold water (effective for products that are immersed in water under its own weight).

Another advantage is that it also cleans the crop. However, various pathogens can spread through water. Therefore, hydro-cooling requires proper water quality and sanitation management.

To prevent bacterial or fungal diseases, some farmers use chemicals. After cooling, the products are stored in refrigerators (up to 2 weeks without ULO and up to 6-8 weeks with ULO).

Comprehensive solutions for cooling berries..

We are competent in all the intricacies of cooling berries and fruits, so all stages of engineering are carried out in accordance with technological requirements. Full “turnkey” construction cycle.

Our experts will help you evaluate different types of refrigeration systems, select the most efficient and cost-effective technical solution that will meet your long-term maintenance requirements and budgets. We provide a warranty on the equipment from the manufacturer and the work performed.